Engineered for a cleaner tomorrow

General Fabrication

Structural Steel, Dryers, Manifolds

Structural Steel

structural steel

All Structural Steel is manufactured to EN1090 execution class 2.

Our new CNC saw drill line cuts and drills to your exact specifications.

- Three independently operating drill heads, each with an automatic tool changer

- Six tool positions for various tasks such as drilling, milling, tapping, countersinking, layout marking and centerpoint marking

- So versatile it can handle almost any production task

- It can drill both web and flanges at the same time

- Profile shapes include - H, I, U, T, L, Square tube, Flat

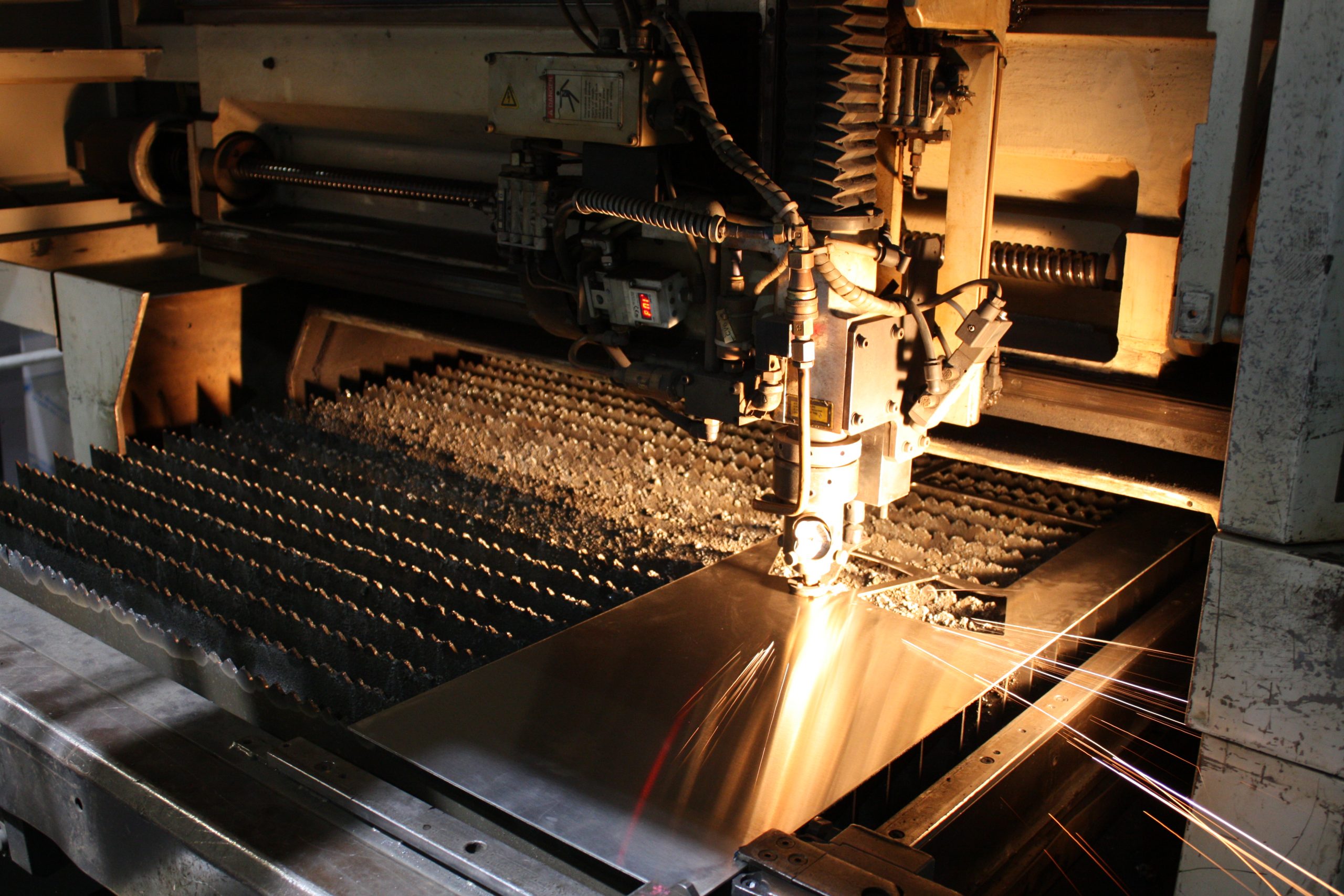

Laser Cutting

We are able to laser cut all types of sheet steel up to 20mm thick – this includes mild steel, stainless steel and aluminum.

- Ideal for a one off prototype or batch work

- No expensive tooling required

- Each component is cut into the most complex shapes with extreme accuracy

- Intricate etching and marking are also possible

- Speed and edge finish is far superior to many other profile cutting methods and requires no de-burring or finishing

Dryers

The Environ Walking Floor Drying Oven has been developed as a robust, flexible and multifunctional machine capable of drying a wide range of materials whilst providing the flexibility to increase material throughput by modular expansion of dryer capacity.

Environ uses a range of construction materials tailored to the individual application.

Use and Applications

- Agricultural - Grain and seeds, corn manure, non-woody biomass

- Biomass - wood chip, forestry residues, arboricultural arisings, compost oversize, sawmill off-cuts

- Waste Management and Recycling - waste quality improvement, RDF, SRF

- Anaerobic Digestion and Biogas - Digestate

- Sewage Sludge Cake - liquid removal from sewage

Biogas Manifolds

We manufacture and install bespoke stainless steel biogas manifolds on Landfill and Anaerobic Digestions sites.

These manifolds are tailored to individual requirements and configurations using TIG welding procedures.

The primary function of a biogas manifold is to manage the flow of biogas from different digesters or collection points to a central system for further use or storage. It connects multiple gas collection pipes into a single line and ensures the even distribution of biogas, maintaining optimal pressure and preventing backflow.

Some key characteristics and functions of a biogas manifold include:

Gas Collection and Distribution: It connects various biogas-producing units (like digesters) to a single gas pipeline that leads to a storage system or directly to a point of use (like a generator or biogas burner).

Pressure Control: The manifold helps maintain consistent pressure within the gas distribution system. Pressure regulators are often integrated into the manifold to control the output pressure of the gas.

Safety: Biogas is highly flammable, so manifolds are typically designed with safety features like relief valves to prevent overpressure and ensure safe operation.

Monitoring and Control: It often comes with sensors or valves that monitor the gas flow, allowing operators to control and adjust the system.

In short, the manifold plays a critical role in the efficient and safe management of biogas in the production system. It ensures that biogas can be effectively collected, stored, and used for energy production or other purposes.